Nylon Net

Brief introduction

It is a chemical fiber woven net made of nylon, nylon, polyester, nylon and other chemical fibers through silk screen mechanical processing. Jinlun has the function of resisting high temperature and alkali, polyethylene has the function of resisting acid, nylon net is the general name of these chemical fiber woven nets. Nylon net includes: (nylon blend), nylon net, polyvinyl chloride net and sunshade net.

Nylon net includes: (nylon blend), nylon net, polyethylene net and sunshade net, which are widely used in plant sunshade, mariculture, flour processing, nylon screen printing, pharmacy, paint filtration, well drilling and guarantee, etc. Jinlun has the functions of resisting high temperature and alkali, and polyethylene has the function of resisting acid.

Material

Nylon 1010, nylon 66, nylon filament, polyester filament, nylon filament, polyethylene filament, etc.

Classification

They are nylon net, nylon net, polyester net, nylon net and polyethylene net.

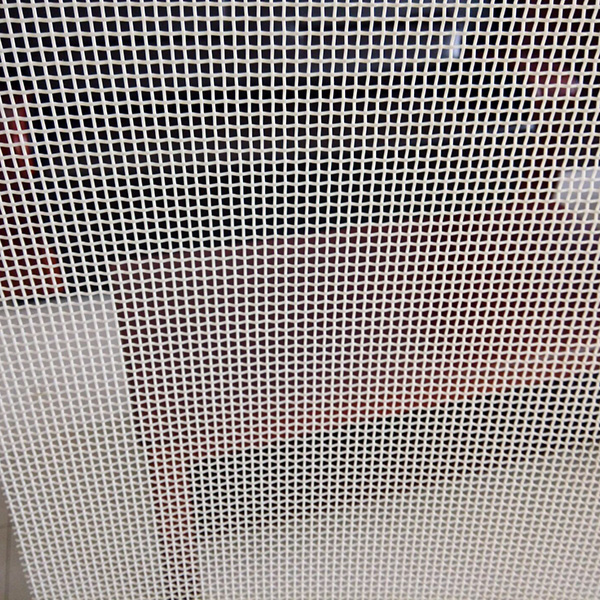

Weave

Generally, plain weave, half twist weave and full twist weave are used.

Advantages

1. High mechanical strength, good toughness and high tensile and compressive strength. The specific tensile strength is higher than that of metal, and the specific compressive strength is equal to that of metal, but its rigidity is lower than that of metal. The tensile strength is close to the yield strength, more than double that of abs. It has strong absorption ability to shock and stress vibration, and its impact strength is much higher than that of common plastics, and is superior to acetal resin. 2. The fatigue resistance is outstanding, and the parts can still maintain the original mechanical strength after repeated bending. Pa is often used in common escalator handrails and new bicycle plastic rims where the periodic fatigue effect is very obvious.

3. high softening point and heat resistance (e.g nylon 46, etc. high crystalline nylon has high thermal deformation temperature and can be used for a long time at 150 degrees. after pa66 is reinforced with glass fiber, its thermal deformation temperature reaches above 250 degrees).

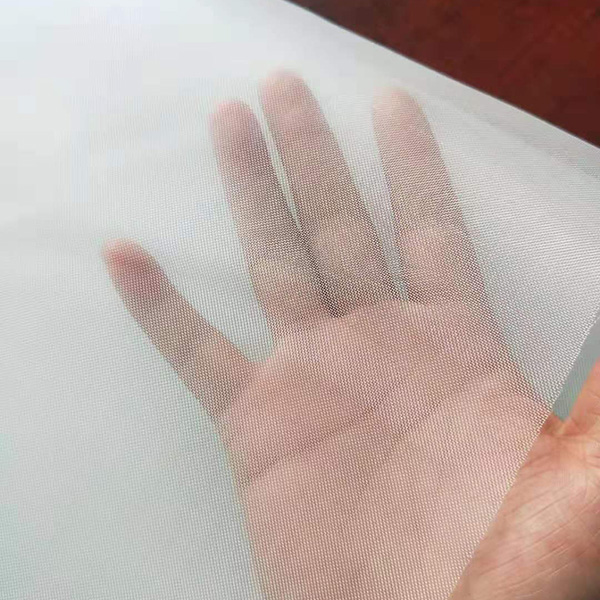

4. Smooth surface, small friction coefficient and wear resistance. Self-lubricating when working as movable mechanical components, low noise, and can be used without lubricant when the friction effect is not too high; If lubricant is really needed to reduce friction or help heat dissipation, water, oil, grease, etc. can be selected. Therefore, as a transmission component, it has a long service life. 5, corrosion resistance, very resistant to alkali and most salt solutions, but also resistant to weak acids, engine oil, gasoline, aromatic compounds and general solvents, inert to aromatic compounds, but not resistant to strong acids and oxidizing agents. Can resist the erosion of gasoline, oil, fat, alcohol, weak alkali, etc. and has good aging resistance. Can be used as packing material for lubricating oil, fuel, etc.

Disadvantages

1. Poor water absorption and dimensional stability.

2. Poor resistance to low temperature.

3. The antistatic property is not good.

4. Poor heat resistance.

Use

Widely used in industrial filtration, petroleum, chemical industry, printing and other products with complete specifications, good quality, special specifications can be customized processing. As well as screen printing, paint filtering, fishing and other industries. Nylon net has the effects of high temperature resistance and alkali resistance, polyethylene net has the effect of acid resistance, and each has its own advantages and disadvantages.

In civil use, it can be blended or spun into various medical and knitwear. Nylon filament yarn is mostly used in knitting and silk industry, such as weaving single silk stockings, elastic silk stockings and other wear-resistant nylon socks, nylon gauze, mosquito nets, nylon lace, elastic nylon outer garments, and various nylon silk or interwoven silk products. Nylon staple fibers are mostly blended with wool or other chemical fiber wool products to make various wear-resistant and wear-resistant clothing materials.

Polyamide is widely used in industry to make cord, industrial cloth, cable, conveyor belt, tent, fishing net, etc. It is mainly used for parachutes and other military fabrics in national defense.

Specifications

The specifications of woven nets are mainly mesh number, wire diameter, aperture, width, etc. Nylon nets are different in specifications due to various types and uses. Generally speaking, the mesh number used for screening and filtration is 60-420 mesh. There are corresponding ratio parameters between wire diameter and mesh, and the smaller the aperture, the smaller the wire diameter. The mesh for fishing is larger.

Inspection

Production and inspection shall be carried out according to the technical requirements and inspection rules of GB/T 14014-1992 "Silk and Synthetic Fiber Screens" and fz 66205—1995 "Silk Screens for Special Industries". The inspection of nylon net mainly depends on whether the mesh number is accurate, processing accuracy, mesh surface defects, large mesh number, wire diameter, etc. conform to the regulations.