Application of flour Web

1 stainless steel screen

Stainless steel screen is woven with stainless steel wire. It is used for sifting bran, crude flour and flour. It has the characteristics of strong penetration, tensile resistance and wear resistance. Its service life is 3-5 times longer than that of polyurethane screen. The commonly used models in flour industry are listed in Table 1. The quality of stainless steel screen depends on the nickel content. Polyurethane screen can replace stainless steel screen.

Table 1 Comparison of old and new stainless steel mesh models

2 polyurethane screen

Grading sieve, powder sieve and cleaner sieve are sold domestically. Silk and chemical fibers are used as raw materials. Polyurethane materials are now mostly used. The screen made of polyurethane has a more rough contact surface, which makes the material flow more slowly. The screen made of polyurethane is hardly affected by material temperature, humidity and climatic conditions. The screen surface is always tight and has a good and lasting separation effect.

1. Grading screen

Table 2 Grading screen cleaner screen type silk and chemical fibre screen

Table 3 Flat woven screen XXX specifications

2. Powder sieve screen

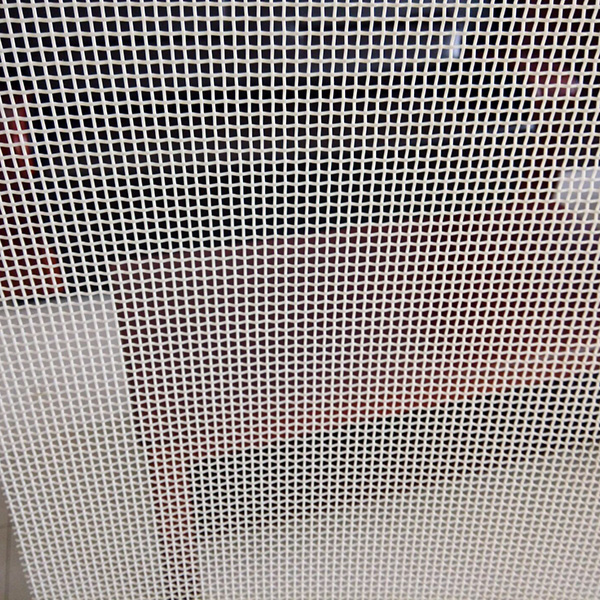

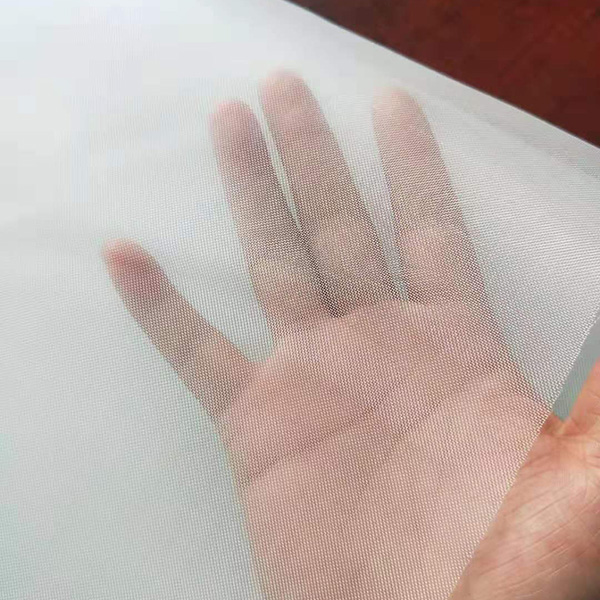

The sieve type of powder sieve ranges from PA6XX to PA15XX. The sieve type of powder sieve is divided into flat weaving (XXX) and semi-twisted weaving (XX). Flat woven screen is mainly used for hard wheat flour sifting, with smaller sieve holes, as shown in Table 3. Semi-twisted screen is used in flour production of both soft and hard wheat. The screen hole is larger, the screen area is larger, and the compatibility is higher. It is more widely used in flour production. See Table 4. The weaving method of screen is shown in Fig. 1.

The material of homemade screen is nylon, silk and polyurethane. From raw materials, production equipment to production process, there has been a rapid development and improvement. After three anti-static treatment, static electricity will not occur in the production process, affecting the effect of screen powder.

The practice of flour mills and flour experts has also proved that the domestic sieve can fully meet the needs of modern flour production and produce first-class flour.

Figure 1 The weaving of screen

Table 4 Semi-twisted screen XX specifications

We usually refer to the sieve of the flour mill, generally referring to the fabric sieve, also known as silk sieve, which is an important auxiliary material of the flour mill. Although the proportion of sieve in the investment of the whole flour mill is very small, it plays a key role, because the flour is finally screened out by the sieve of the flour mill. Today, as a professional flour mill.

Talking about the Key Points of Selecting Flour Screen

1. Sieve opening scale: From the above, we can see that because of the existence of a variety of representations, it is better to select according to this actual scale.

2. Wear resistance: To a large extent determines the service life of the screen. Among all the data currently used, nylon has the best wear resistance, polyester is only 70%, and silk is the worst. For the screen with the same data, the thicker the diameter, the better the wear resistance. A wheat flour mill is a wheat flour mill.

3. Elongation: From Table 1, silk screen is significantly lower than polyester and nylon nets, but now, most polyester and nylon nets have to be heat-set after weaving, to prevent mesh deformation as far as possible. Therefore, it is similar to the application of silk screen. Flour mill is also called flour mill, or flour machinery.

4. Antistatic property: Every flour screen requires antistatic treatment, because the contact and friction between fibers and fibers, fibers and materials, will form the transfer of electric charge between the fibers surface, resulting in electrostatic phenomenon, and because of the finer particle size of flour, it is easy to be attracted by electric charge to form screening difficulties, and even paste nets.

What is the finest flour?

The finest flour is 140 meshes, the common flour is 80 meshes, and the refined flour is 120 meshes.

The mesh refers to the number of holes per inch of screen mesh. The 50 mesh refers to 50 holes per inch and 500 holes per inch. The higher the number of holes, the more holes there are. In addition to representing the hole of the screen, it is also used to indicate the particle size through the screen. The higher the mesh number, the smaller the particle size.

The roughness of flour indicates the degree of grinding during wheat processing. Generally speaking, the finer the flour, the greater the degree of damage. At present, in order to reduce ash content, increase whiteness and equip sieve silk denser, many flour mills in our country produce flour with high fineness, so the degree of starch damage increases, and the flour with high damage starch will obviously change the flour characteristics.