Introduction of nylon mesh

Nylon is developed by carothers, an outstanding American scientist, and a research team under his leadership. Nylon is the first synthetic fiber in the world. Nylon is an expression of polyamide fiber.The appearance of nylon has changed the appearance of textiles. Its synthesis is a major breakthrough in the synthetic fiber industry and a very important milestone in polymer chemistry.

Structure

Polyamide is commonly known as nylon (Nylon), and its English name is Polyamide (pa) with a density of 1.15g/cm3. Polyamide is a general term for thermoplastic resins containing repeating amide groups —[nhco]— in the molecular main chain, including aliphatic pa, aliphatic-aromatic pa and aromatic pa. Among them, aliphatic pa has many varieties, large output and wide application. Its name is determined by the specific carbon number of synthetic monomer. Created by famous American chemist carothers and his research team. Nylon is a term for polyamide fiber (nylon), which can be made into long fibers or short fibers. Nylon is the trade name of polyamide fiber, also known as nylon. The English name polyamide (pa for short) is an aliphatic polyamide whose basic composition is linked by amide bond-[NHCO]-.

Molecular structure

Polyamide fibers commonly used in molecular structure can be divided into two categories.

One is poly hexamethylenediamine adipate, which is obtained by condensation polymerization of diamine and diacid.

The chemical structural formula of its long chain molecule is:

H—[HN(CH2)XNHCO(CH2)YCO]—OH

The relative molecular weight of nylon is generally 17,000-23,000. Different nylon products can be obtained according to the different carbon atoms of diamine and diacid, and can be distinguished by the number added to nylon, wherein the former number is the carbon atoms of diamine, and the latter number is the carbon atoms of diacid. For example, nylon 66 shows that it is prepared by polycondensation of hexamethylene diamine and adipic acid. Nylon 610 is made of hexamethylene diamine and sebacic acid.

The other is obtained by polycondensation or ring-opening polymerization of caprolactam, and the chemical structural formula of the long-chain molecule is

H—[NH(CH2)XCO]—OH

which can be named according to the number of carbon atoms contained in the unit structure. For example, nylon 6 shows that it is obtained by ring-opening polymerization of caprolactam containing 6 carbon atoms.

Nylon 6, nylon 66 and other aliphatic nylon are all composed of linear macromolecules with amide bonds (—nhco—). Nylon molecules have-—co—-,-—nh—-groups, which can form hydrogen bonds between molecules or within molecules, and can also combine with other molecules, so nylon has better moisture absorption ability and can form better crystal structure.

The-CH2-(methylene) in nylon molecule can only generate weak van der Waals force, so the molecular chain curl of the-CH2-segment is relatively large. Due to the different number of nylon today-—ch2—-,the bonding forms of intermolecular hydrogen bonds are not completely the same, and the probability of molecular curling is also different. In addition, some nylon molecules have directionality. The structural properties of fibers are not completely the same with different molecular directionality.

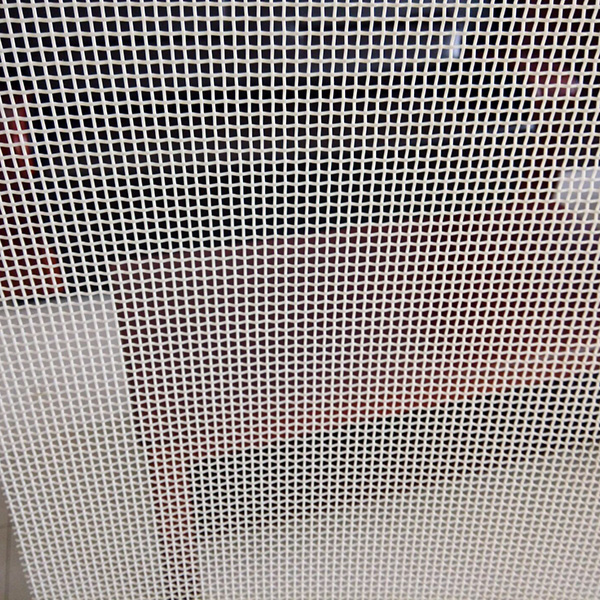

Morphological structure

Morphology The morphology of nylon produced by melt spinning method observed under microscope has circular cross section and no special longitudinal structure. Filamentous fibril tissue can be observed under an electron microscope, and the fibril width of nylon 66 is about 10-15nm. If a special spinneret is used, nylon with various special cross-sectional shapes can be made, such as polygonal, multilobal, hollow and other special cross-sections. Its focused structure is closely related to stretching and heat treatment in spinning process. The macromolecular main chains of different chinlon are formed by connecting carbon atoms and nitrogen atoms.

Special-shaped fibers can change the elasticity of the fibers, make the fibers have special luster and bulkiness, and improve the cohesion and covering ability of the fibers, as well as the anti-pilling and static electricity reducing properties. For example, triangular fibers have flashing effect; Pentalobal fiber has luster like fat light, good hand feeling and anti-pilling. Hollow fibers have small density and good heat retention due to the cavity inside.

Polyamide (pa, commonly known as nylon) was the first resin developed for fiber by dupont Company in the United States and was industrialized in 1939. The development and production of injection molded products began in the 1950s to replace metals to meet the requirements of lightweight and cost reduction of downstream industrial products. Polyamide has many repeated amide groups in its main chain. It is called nylon when used as plastic and nylon when used as synthetic fiber. Polyamide can be prepared from diamine and diacid, or it can be synthesized from omega-amino acid or cyclic lactam. According to the number of carbon atoms contained in diamine and diacid or amino acid, many different polyamides can be prepared, and there are dozens of varieties of polyamides, among which polyamide -6, polyamide -66 and polyamide -610 are most widely used. The link structures of polyamide -6, polyamide -66 and polyamide -610 are [nh(ch2)5co], [nh(ch2)6nhco(ch2)4co] and [nh(ch2)6nhco(ch2)8co], respectively. Polyamide -6 and polyamide -66 are mainly used to spin synthetic fibers, called nylon -6 and nylon -66. Nylon -610 is a thermoplastic engineering plastic with excellent mechanical properties.

PA has good comprehensive properties, including mechanical properties, heat resistance, abrasion resistance, chemical resistance and self-lubricity, low friction coefficient, certain flame retardancy, easy processing, and is suitable to be filled with glass fibers and other fillers to enhance modification, improve performance and expand application range.

There are many varieties of pa, including pa6, pa66, pall, pal2, pa46, pa610, pa612, pal010, and many new varieties of semi-aromatic nylon pa6t and special nylon developed in recent years. Nylon -6 plastic products can be made by using sodium metal, sodium hydroxide and other main catalysts and n- acetyl caprolactam as cocatalyst, so that δ-caprolactam is directly prepared by negative ion ring-opening polymerization in a model, which is called cast nylon. This method is convenient for manufacturing large plastic parts.

Use

Polyamide is mainly used for synthetic fibers. Its most prominent advantages are that its abrasion resistance is higher than all other fibers, 10 times higher than cotton's abrasion resistance and 20 times higher than wool's. Adding some polyamide fibers into blended fabrics can greatly improve its abrasion resistance. When stretching to 3-6%, the elastic recovery rate can reach 100%; Can withstand tens of thousands of twists without breaking.

The strength of polyamide fiber is 1-2 times higher than cotton, 4-5 times higher than wool, and 3 times higher than viscose fiber. However, polyamide fiber has poor heat resistance and light resistance and poor retention, and the clothes made of polyamide fiber are not as crisp as polyester fiber. In addition, nylon -66 and nylon -6 used for clothing both have the disadvantages of poor hygroscopicity and dyeability. For this reason, new varieties of polyamide fibers-polyamide -3 and polyamide -4 have been developed, which have the characteristics of light weight, excellent wrinkle resistance, good air permeability, good durability, dyeability and heat setting, etc. Therefore, they are considered to have great development prospects.

This kind of product has a wide range of uses, is a good material to replace steel, iron, copper and other metals with plastic, and is an important engineering plastic. Cast nylon widely replaces wear-resistant parts of mechanical equipment and copper and alloy as wear-resistant parts of equipment. It is suitable for making wear-resistant parts, transmission structure parts, household electrical appliance parts, automobile manufacturing parts, screw rod prevention machinery parts, chemical machinery parts and chemical equipment. Such as turbine, gear, bearing, impeller, crank, instrument panel, drive shaft, valve, vane, screw rod, high pressure washer, screw, nut, sealing ring, shuttle, sleeve, sleeve connector, etc.

Replacing metals such as copper polyamide is widely used to replace metals such as copper to manufacture bearings, gears, pump blades and other parts in machinery, chemical industry, instruments, automobiles and other industries due to its non-toxicity, light weight, excellent mechanical strength, wear resistance and better corrosion resistance. Polyamide has high strength after being melt spun into silk.

It is mainly used as synthetic fiber and can be used as medical suture. Used for various medical treatment and knitwear. It can be blended or spun into various medical treatment and knitwear.

Nylon filament yarn is mostly used in knitting and silk industry, such as weaving single silk stockings, elastic silk stockings and other wear-resistant nylon socks, nylon gauze, mosquito nets, nylon lace, elastic nylon outer garments, and various nylon silk or interwoven silk products. Nylon staple fibers are mostly blended with wool or other chemical fiber wool products to make various wear-resistant and wear-resistant clothing materials.

Nylon is widely used in industry to make cord, industrial cloth, cable, conveyor belt, tent, fishing net, etc. It is mainly used for parachutes and other military fabrics in national defense.