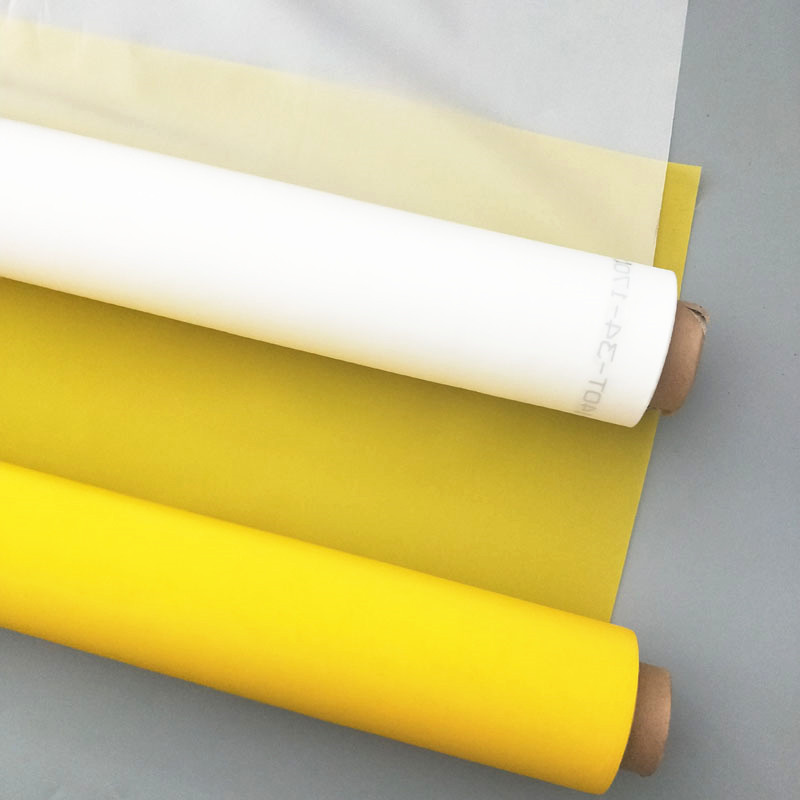

PCB Screen Printing Mesh

| Material | Polyester; Nylon; Stainless steel |

| Specification | 36T-165T |

| Mesh count | 90-420 mesh |

| Woven type | Plain woven |

| Color | White ; Yellow |

| Width | 127cm,145cm,165cm,2.50cm etc,customize |

| Production type | Roll cloth |

| The length of roll | 30-80m; Can be customized length; Customize |

PCB Screen printing mesh is used in the printed circuit board industry, which remains the most economical and efficient way to print PCB solder masks, legends and single layers.Screen printing mesh has been an important manufacturing process for the printed circuit industry for more than half a century.

| Material | Polyester; Nylon; Stainless steel |

| Specification | 36T-165T |

| Mesh count | 90-420 mesh |

| Woven type | Plain woven |

| Color | White ; Yellow |

| Width | 127cm,145cm,165cm,2.50cm etc,customize |

| Production type | Roll cloth |

| The length of roll | 30-80m; Can be customized length; Customize |

Advantages

- Wide ranges of mesh counts for all requirements and accuracy of screen printing.

- Ideal for pcb, membrane switches, touch screens and thickfilm screen printing.

- Maximum efficient and reproducible for glass screen printing production.

- High tensile strength and dimensional stability.

- Extended lifetime and best ink release behavior.

- Custom service for stencil makers and solar panel printers.

- Reduce production costs and production loss for your glass printing.

- Competitive prices help you occupy more markets in your local markets.

Although there are other technologies competing with it, screen printing is still the fastest and most economical method for large-scale production of printed circuits. Screen printing mesh is the most important part of printed circuit board. It is the key to control ink flow and printing thickness. In addition, the excellent combination of screen printing mesh and screen printing material is also high quality. An important factor in high-precision screen printing.

- Wide ranges of mesh counts for all requirements and accuracy of screen printing.

- Ideal for pcb, membrane switches, touch screens and thickfilm screen printing.

- Maximum efficient and reproducible for glass screen printing production.

- High tensile strength and dimensional stability.

- Extended lifetime and best ink release behavior.

- Custom service for stencil makers and solar panel printers.

- Reduce production costs and production loss for your glass printing.

- Competitive prices help you occupy more markets in your local markets.

- Etch & plating resist

- Solder mask

- Legend marking

- Carbon paste

- Plug paste

- Via hole filling

- Surface mount adhesive

- Heat sink paste

Screen printing pcb

Screen printed pcb

Thickfilm applications

- Thickfilm

- RFID

- Fuel cells

- Batteries

Screen printing thickfilm

Screen printed battery

Dials

- Solid color

- Translucent ink

- Metallic and fluorescent

- Adhesive

- Varnish

Screen printing dials

Screen printed dials

Touch screens

- Etch-resistant

- Conductor paths

- ITO insulation

- Edge masking

- Adhesive printing

Screen printing touch screens

Screen printed touch screen