What are the factors affecting the service life of filter bag

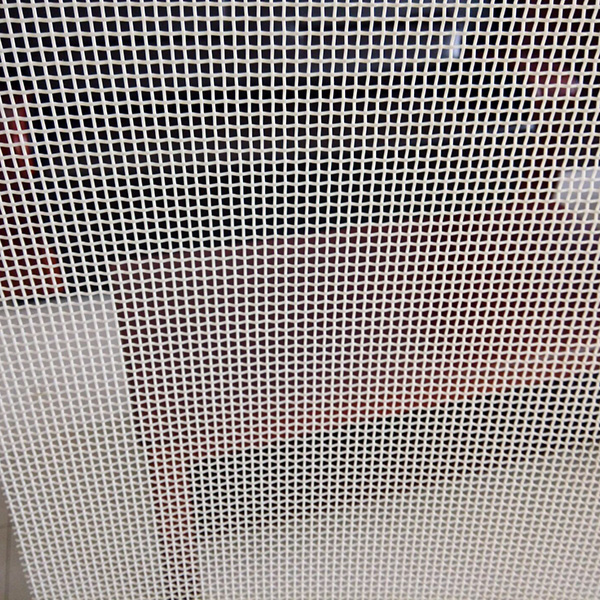

The material of the filter bag is nylon, polypropylene, polyester, stainless steel and polytetrafluoroethylene. According to the size of the filter, there are: bag 2, bag 1, bag 5, bag 4, bag 3 (from large to small).

Factors affecting the service life of filter bag

Material and sewing quality of cloth (filter) bag

The material of the bag itself will play a decisive role. As the glass fiber filter bag needs to be treated with silicone oil and polytetrafluoroethylene, it is equally important whether the treatment process is carried out according to the requirements. When sewing the cloth (filter) bag, the suture itself also needs to be treated. It is required to use the same material as the dedusting cloth (filter) bag to ensure the overall life of the filter bag.

The support ring shall be made of stainless steel, and the sewing method also has a great influence on the service life of the dedusting filter bag.

In order to save investment, carbon steel support ring is used. After a few months, the support ring is rusted, which causes the glass fiber cloth (filter) bag to wear through. The distance between the support rings of the cloth (filter) bag should not be too small, generally 1000-2000mm, and the lower part of the cloth (filter) bag should take a low value to reduce wear.

Correct selection of equipment resistance

If a pressure drop of 3000-4000pa is adopted, it is very beneficial for dust removal by cloth (filter) bag, but the cloth (filter) bag and seam joint will be damaged quickly. The lower the pressure drop is, the longer the life of cloth (filter) bag is, but in fact it is not

If the pressure drop is low and the dust is fine, the cleaning cycle will be shortened and the cleaning frequency will be increased, which will also affect the life of the filter bag of the dust remover. The pressure drop is controlled at about 1500pa, which is beneficial to the ash cleaning effect and the life extension of the cloth (filter) bag.