Some points should be paid attention to when selecting filter bag for wet gas

The liquid filter bag can have stainless steel ring, PP ring and PE plastic ring, including various bag bottom and bag top designs. The filtrate surface of the liquid filter bag is treated with special singeing, which not only effectively prevents the fiber from separating and contaminates the filtrate, but also avoids the filter hole from being excessively blocked and shortens the service life of the filter bag caused by the traditional rolling treatment

Some points should be paid attention to when selecting filter bag for wet gas

When high temperature and high humidity exist at the same time, it will affect the temperature resistance of the filter bag, especially for the materials with poor hydrolysis stability such as cotton fiber, polyester and amide, which should be avoided as much as possible.

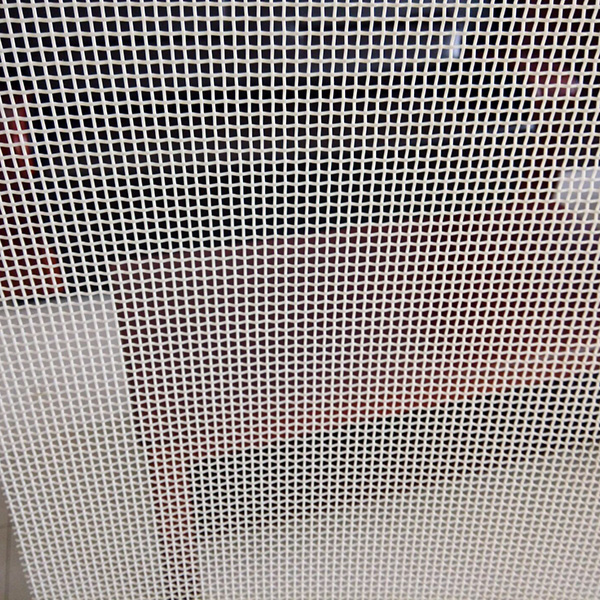

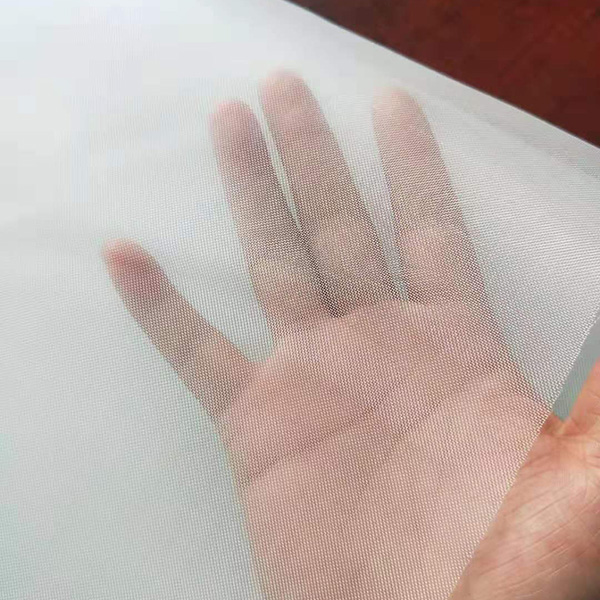

The wet gas makes the dust collected on the surface of the filter bag wet and stick, especially for water absorption, deliquescence and wet dust. For this reason, the filter bags with smooth surface, long fiber and easy to remove dust, such as nylon and glass fiber, should be selected, and silicone oil and fluorocarbon resin should be used for impregnation treatment, or acrylic acid and polytetrafluoroethylene should be used for coating treatment on the surface of the filter bags.

Plastic burning board and film covering material have excellent moisture resistance and easy ash removal performance. However, as a high humidity gas, it should be waterproof, oil proof and dust removal cloth bag.

The inlet temperature of the dust containing gas of the dust remover shall be higher than the dew point temperature of the gas by more than 30 ℃, so as to avoid bag pasting.

Chemical properties of gases. There are many kinds of chemical components such as acid, alkali, oxidant and organic solvent in various furnace tail gas and chemical waste gas, and they are often affected by many factors such as temperature and humidity. For this reason, the dust removal filter bag shall be selected with consideration to avoid losses.

For the wet gas, the circular filter bag should be used in the design of dedusting filter bag, and the flat filter bag and diamond filter bag with complex shape and compact arrangement should not be used as far as possible (except for plastic burning plate).

.jpg)