Nylon fiber has many uses

Super nylon. Nylon fiber can be used for many purposes, from clothing, carpet, rope to data line of microcomputer. Researchers at the University of North Carolina's School of textiles are trying to improve the fiber, and it is reported that the strongest aliphatic nylon fiber has been developed.

Dr. Tonelli, Professor of polymer science, and Richard, assistant professor of textile engineering, chemistry and natural sciences. Dr. ketak is working on a way to produce higher strength nylon fibers without expensive, messy processes. They used aliphatic nylon or nylon for their research. The carbon of this nylon helps to use straight chain or open type branch chain to connect the once, focusing on the large acyclic chain.

More robust aliphatic nylon can be used in ropes, loading and unloading belts, parachutes and car tires, and may produce composition information suitable for high temperature use. The findings were presented at the annual meeting of the American Chemical Sciences in Philadelphia and published in the journal polymer timing.

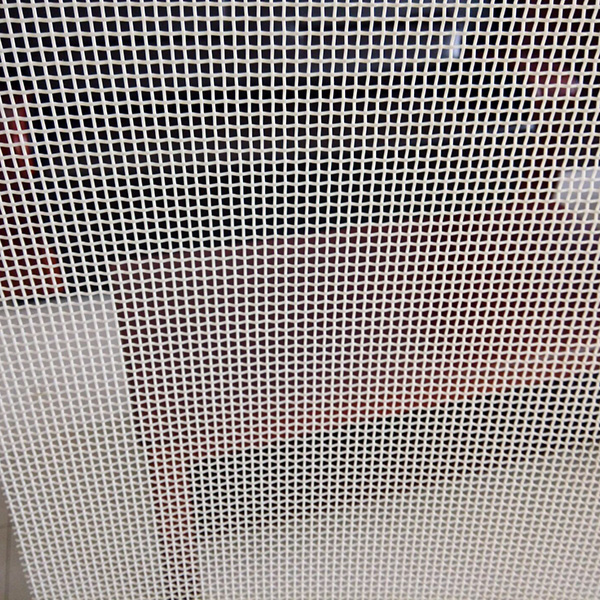

The fibers are made from polymers that may include many units of long-chain molecules. When these polymer chains are structured, the polymer will become crystalline. These surrounding polymers need to be stretched, and if they are to be made into stronger fibers, they need to eliminate their elasticity. Joining hydrogen in the nylon chain can avoid stretching, so overcoming this bond is a key factor for stronger nylon fibers.

Super strong fiber, taking Kevlar fiber as an example, is made from aromatic nylon polymer. It is very stiff. Long chain includes ring chain. Aromatic nylon is very difficult to make, so it is very valuable. This discovery can deal with the problem that nylon can dissolve in gallium trichloride, and can effectively break the problem of hydrogen bonding. Polymer chain extension is allowed.