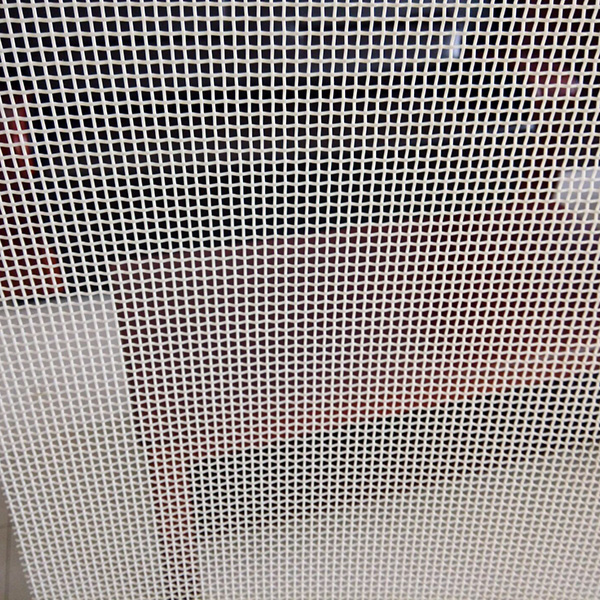

Characteristics of screen printing fabric

The universality of screen print material:

Mesh for screen printing materials range from large curtain wall advertisements to micro circuit boards, from plane materials with high flatness to curved surface materials with large radian, from common paper, PVC board, sapphire glass, ceramics, etc. objects of various shapes can be printed on the screen.

The universality of printing:

Simple silk screen printing can only screen, ink and scraping glue can meet the manual printing, the investment amount can be as low as 1000 yuan RMB, low investment makes the silkscreen printing mesh process more common. The high-end screen printing equipment can be specially customized to realize the pre-treatment (cleaning), automatic feeding, printing, automatic size and appearance detection, automatic baking, automatic receiving, etc. The commercial end invests hundreds of thousands of RMB to millions of RMB. This kind of mesh screen printing is mainly used in the printing of consumer electronic screens and circuit boards because of its less people and commercial efficiency.

Diversity of forms of expression:

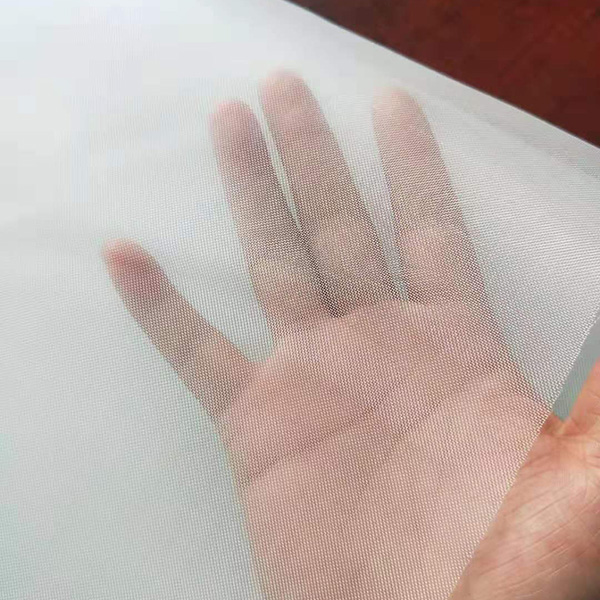

With the corresponding silk screen printing, the film thickness can reach 6-300um. Because of its thick film, high masking rate and strong three-dimensional sense, the modern screen printing shop can print three-dimensional effect, holographic effect, mirror effect and even photochromic effect. Combined with different ink forming characteristics, the film with strong hydrophilic or hydrophobic effect can be printed. In addition, there is a certain distance between the fabric mesh and the substrate. When printing, the screen and the substrate are in linear contact. Therefore, even if the substrate is flat and fragile, it is not a problem. This feature makes the silk screen printing glass widely used in the decorative glass industry.