Application of screens in screen printing industry

Screen classification

The main raw materials for screen production in China are mulberry silk, nylon wire and metal wire. The main types of screen can be produced are silk screen, synthetic screen and metal screen.

1. Silk screen

Silk screen is a kind of screen made from animal fibers and silk. It includes CB and CQ.

C - Represents mulberry silk.

B - Represents half-skein or plain weave.

Q - Represents the whole skein weave.

Therefore, we use CB to denote the screen of half-skein or plain weave yarn made from silk and CQ to denote the screen of full-skein weave made from silk.

1. synthetic sieve

Synthetic fibre screen is a kind of screen made from synthetic fibers, mainly nylon screen and polyester screen. JF, JP, DF and DP are used respectively.

J - stands for nylon.

D - stands for polyester.

F - Represents Fang Ping Organization.

P - Represents plain weave.

Therefore, JF stands for square screen made of nylon yarn. JP stands for plain weave screen made of nylon yarn. DF denotes a flat-textured screen made of polyester filament. DP means plain weave screen made of polyester filament.

This kind of screen is produced on shuttle looms. Now screening production units use shuttle looms to produce, the product quality is better than shuttle looms. In order to show the difference, use JFP, DFP... P means that the product is produced on electric shuttle looms.

2. metal screen

Metal screen is a kind of screen produced by drawing ferrous or non-ferrous metals. It has stainless steel screen, brass screen and phosphor-copper screen.

2. selection of screen

What sieve specifications the user chooses depends on:

1) Types of ink or printing paste used in printing.

2) Fineness of printed patterns and number of color sets.

3) How about the material and performance of the undercloth used for printing?

The main parameters for selecting screen are as follows:

1. Number of meshes

There are two methods of calculation:

Metric system: that is, the number of longitude (latitude) lines in the length of one centimeter (centimeter). For example, JF42, refers to the nylon square flat organization of a centimeter 42 mesh screen.

British system: that is, within an inch of length, the number of warp (weft) lines, such as nylon 120 mesh, refers to 120 warp (weft) lines in an inch.

2. wire diameter

The diameter of raw material monofilament used in weaving screen is expressed in micron (micron).

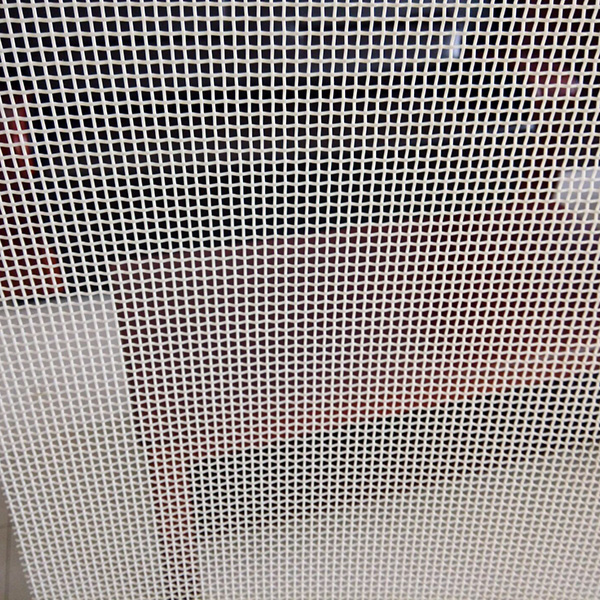

3. mesh size

That is, the size of the opening, which indicates the relationship between the number of longitude or latitude lines per centimeter and the thickness of each filament, is the gap between the two filaments, expressed in microns.

4. Opening rate

That is, the opening area refers to the ratio of the area of one centimeter of internal mesh to that of one centimeter, usually expressed as "%", which represents the proportion of screen ink or slurry passing through the screen, for example, the opening rate of jf42 is 25%. Represents that 75% of the ink or slurry is left on the screen during the printing process, and only 25% of the ink or slurry passes through.

5. Screen Thickness

Like the opening rate, the thickness of screen directly affects the amount of ink or slurry deposited on the fabric. The thickness of screen is related to the thickness of raw silk used for screen, which is generally about 90%~95% of warp silk warp and weft silk warp.

6. Ink permeability

That is, the capacity of ink or paste for all meshes in a square metre area, which is related to the number of silk warps and meshes used in weaving screen, expressed as "cm3/m2".

Nowadays, nylon and polyester monofilament screens are widely used in our country, while other screens such as mulberry silk screens and monofilament synthetic screens are less used, so the selection of nylon and polyester monofilament screens is introduced as follows.

Nylon (nylon) screen: high strength, good elasticity, flexibility, so the printing effect on rough surface materials is better, usually used for products with low precision requirements, and because of its good alkali resistance, it is often used in printing with alkaline ink or slurry nylon screen.

Polyester screen: Because polyester monofilament has good molecular structure, it has good positioning, so the size is stable. It is often used in high-quality products and multi-color printing plays, because the single filament elongation is small, it can maintain the size stability under various temperature and humidity conditions, and because it has good acid resistance, so it is used in acid sleeve ink or in multi-color printing theatre. Polyester screen is often used in the printing of slurry.