18 Mar, 2020

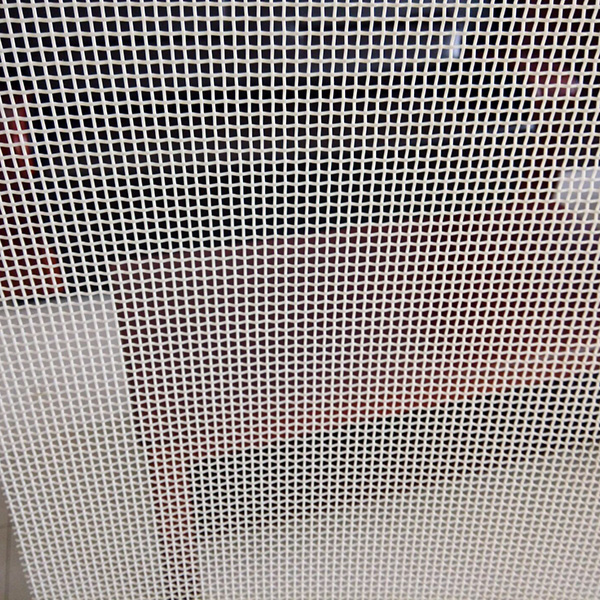

Screen printing mesh number selection

The following three factors need to be considered

1. Ink used:

(1) General water-based ink is suitable for thicker silk screen (120-180 mesh/inch)

(2) When printing advertisements, electrical appliances, etc., solvent ink shall use medium mesh silk screen (195-420 mesh/inch)

(3) UV ink is printed with high mesh (305-510 mesh/inch);

(4) The pigment particles of common ink are relatively fine, and the ink has good passing ability. This ink can also pass well when using high mesh screen. However, ink with high pigment concentration has poor permeability even though its particles are fine.

2. Type of substrate:

(1) For the absorbent printing stock with rough surface, to achieve the best coverage rate of ink layer, more ink is needed, so thicker printing mesh cloth is selected;

(2) the smooth surface of the non-absorbent substrate requires relatively less ink, so choose a higher mesh screen.

3. The screen mesh number matches the original image:

The number of screens selected should be sufficient to match the image on the plate film, i.e. to ensure that the thinnest image area has sufficient polyester screen support.

If other factors are excluded, the mesh number of the screen is less than 180 meshes, and the tooth shape of the printed image edge is obvious after the printing plate is made, while the tooth shape of the printed image edge is smooth and not obvious after the plate making is made.

According to experience, when printing products with small images, small characters and thin lines, and the thinnest line is about 0.2mm( 200um), a screen with more than 250 meshes must be used for plate making.

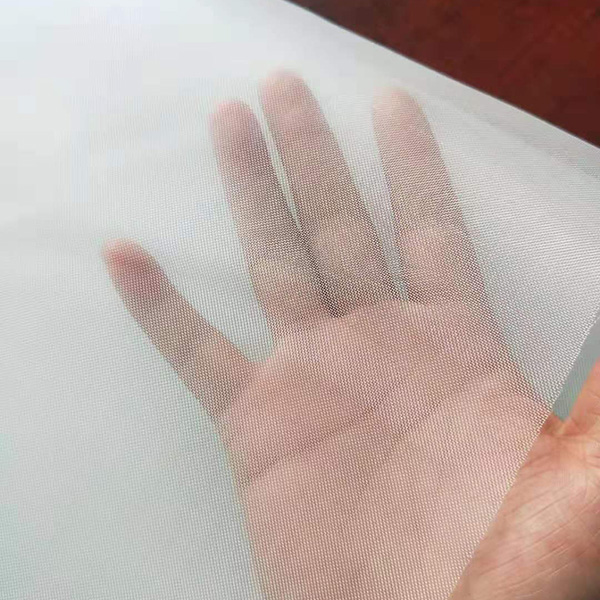

If the accuracy of the printed product is required to be high, the error is less than 3/1000, and the image is very small (about 5X 5CM), the wire mesh should be selected. Polyester screen can be considered for high precision screen with error greater than 3/1000.

Previous:Nylon fiber has many uses