Production of printing nets

It is the quality of screen printing that determines the quality of printing. How to produce high quality screen printing is a direct issue for printing enterprises to consider. Here we will learn about the process of screen printing screen printing.

Generally speaking, due to the different photosensitive materials used in screen plate making, the production process is also different.However, no matter which process is adopted, the following steps are indispensable in the process of screen plate production: selection of screen and screen frame, drawing, washing, etc. Photosensitive materials, exposure, development, drying.

1. Exposure

The film film film is pasted on the screen printing surface (convex surface), and then exposed in the vacuum exposure machine.

The exposure time depends on the thickness of the photosensitive glue, the energy of the exposure lamp and the requirements of the screen plate (general circuit, welding resistance, etc.).

Characters, the exposure time required by screen plate is different.) Generally, the exposure time should be measured by means of an exposure calculating ruler before use.

Then the exposure time of the screen plate is fixed.

Step: Firstly, Filin uses a magnifying glass to correct the longitude and latitude of the screen, and the lines should be parallel and perpendicular to the screen. (Note: Especially lines and characters)

Put the calibrated net into the exposure machine, adjust the time, and turn on the exposure machine switch after sucking into vacuum.

Attention: Short exposure time will cause problems such as sensitive glue easy to fall off, line coarsening, solder blocking point not firm, character number not firm, etc. And long exposure time will cause quality accidents such as endless development or line thinning. Therefore, In particular, it is suggested that the accurate exposure time should come from scientific practice, and the exposure time should be measured with an exposure ruler before exposure in production. Then fix the exposure time, do not do things by experience, blindly work.

2. Development

Remove the screen from the exposure machine, remove the negative, wet both sides of the screen with gentle and pressure-free cold water (20-30 C) for about 30-60 seconds, then rinse the screen thoroughly with a high-pressure water gun until the image is displayed, then absorb the excess water around with a water absorbent cloth, and put the screen into 30-40 C. Dry in oven.

Step: Wet the exposed screen with water for about 1 minute, flush the screen with high pressure water until it is completely clear; Defects such as fur edge. _

3. Check standby

Check whether the screen plate meets the requirements of production and processing after drying. If it meets the standards, do a good job of sealing the screen immediately so that the production personnel can use it. If there is no requirement, repair or re-manufacture it immediately.

4. Detailed Interpretation of Screen Plate Making Process

Generally speaking, the production process of screen plate is different because of the different photosensitive materials used. However, no matter which process is adopted, the following steps are indispensable in the process of screen plate production: screen and screen frame selection, screen drawing, screen washing, coating photosensitive materials, exposure, development and drying. Next, we will have a detailed understanding of the operation methods and precautions of each process. _

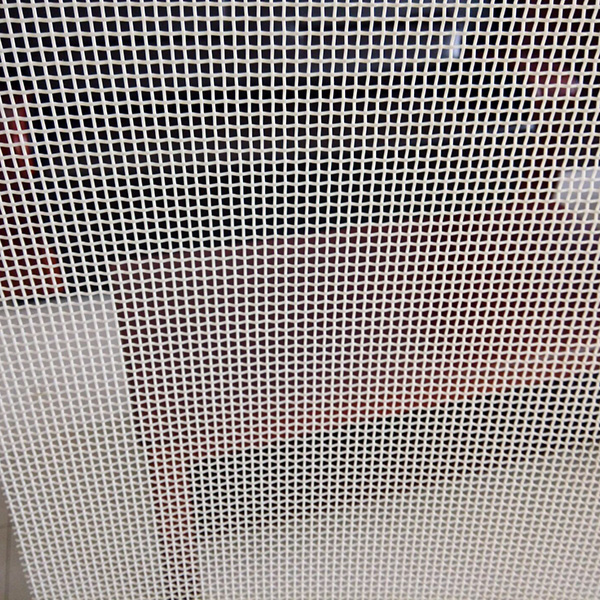

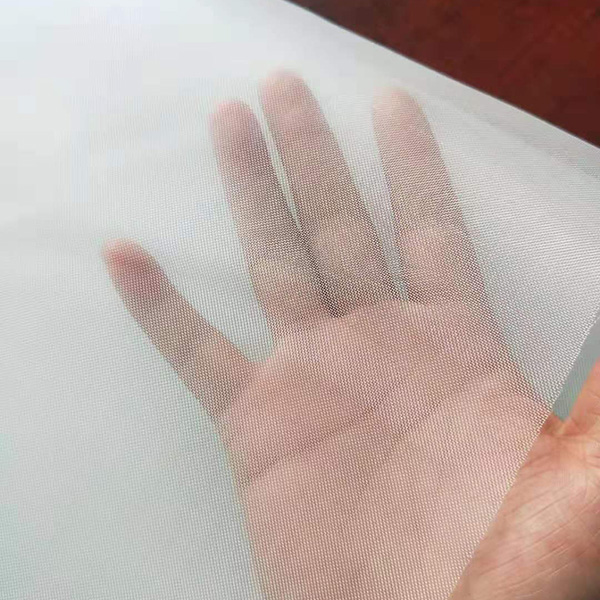

1) Screen selection

At present, there are many kinds of silk screen on the market, such as silk screen, nylon screen, polyester screen, metal screen and so on. Generally, considering the cost and applicability, nylon screen is the most common type of silk screen on the market. The characteristics of nylon screen are introduced. The nylon screen has many characteristics, such as smooth surface, good ink permeability, good softness, good elasticity, strong adaptability, good tensile strength, elasticity and friction resistance, good nodule fastness, long service life, acid resistance, chemical resistance and organic solvent performance. Therefore, it is favored by fine printing and fine printing. Line drawing pattern and dot printing are widely used.

Cautions for use: In addition to the above advantages, nylon wire mesh also has some disadvantages, such as high elongation, low heat resistance, etc. Therefore, the following points should be paid attention to when nylon wire mesh is available:

A. Because of the high elongation of nylon silk screen, it is necessary to use strong screen frames and stretchers in printing;

B. In view of the disadvantage of low heat resistance of nylon screen, it is not necessary to fix the screen by thermal solution in printing;

C. Ultraviolet radiation also has some effects on nylon screen, so we should avoid light when keeping nylon screen or its corresponding screen.

2) Choice of Frame

According to the material, the net frame generally has wooden frame, aluminium frame, stainless steel frame, commonly used wooden frame, aluminium frame, iron frame and so on. _

A. Wooden Frame: It's cheaper and easier to make. It can be stretched by hand or by machine. But its shortcoming is that it's strong enough and easy to be deformed. It's only suitable for low price. Precision product printing is not suitable for fast and high precision screen printing. In addition, the screen pulled out by wooden frame is easy to relax and has poor recovery. _

B. Iron frame: Compared with wooden frame, it has the characteristics of stable size and durability, but its weight, rust prone, inconvenient to use, and can only be used with mechanical tension net.

5. Pull the net

In plate making, the drawing methods can be divided into three types: manual, mechanical and pneumatic. For example, the silk printing factory does not require high precision, and generally adopts the first two methods; for higher requirements, the last pneumatic drawing machine can be used. The pneumatic drawing machine is suitable for high precision screen drawing. Its characteristics are uniform tension, easy to use, and can meet different requirements of tension, especially suitable for drawing high-precision printing screen plate.

6. Washing the Net

Printing and plate making usually uses special chemicals to wash the screen (such as defilm water, diluent, detergent, etc.), but this method consumes time, so it is a little troublesome for those aging factories. Here we share an effective method: choose detergent detergent, such as detergent powder. Stain elimination, wetting the mesh plate, and then polishing with cotton cloth, this method is not only fast dirt, but also conducive to the adhesion of photosensitive glue, it can be said to be double carving with one sword. (Note: For the above method, double-sided polishing is needed, while for the front polishing, the force should be lighter to avoid the net yarn falling off.) Wash the net and cover it. Put the net in the dryer for drying.

7. Coating

1) Selection of Photosensitive Materials

At present, there are two kinds of photosensitive materials in the market. One is photosensitive adhesive. Its advantages are simple technology, economy, practicality, fast exposure speed, durable screen plate, easy film removal and excellent solubility. The other is photosensitive film, which is a kind of pre-sensitized photosensitive material. It is affixed to the screen before exposure. It has hydrophilicity, strong image resolution, good line sharpness and durability. Its performance is better than photosensitive film. Because of its hydrophilicity, it is commonly called "Shuifeilin". Generally speaking, the requirements of printing for photosensitive materials are: the film formed by photosensitive materials should be suitable for the performance requirements of different types of ink, and has considerable printing resistance, can withstand the scraping of the scraper for a considerable number of times, has good adhesion with the screen, does not produce film breakdown during printing, is easy to peel off, and is conducive to the regeneration of screen plate. Use.

2)Coating

Requirements: Photosensitive glue, sizing device (scraper), grid platform. In the market, the photosensitive paste is required to be used by oneself. It can be humidified by hot water first, then poured into the photosensitive paste and evenly adjusted. It can be used after several hours. Small plants can be sizing by plate makers, while large plants have automatic sizing machines with uniform thickness. The operation steps are as follows:

(1) Place the dry stand-by screen on the gelatinizing table, place the screen steadily, and pour the photosensitive glue into the scraper. (Note: Appropriate amount)

(2) Using a scraper, the photosensitive adhesive is evenly coated on the screen, first on the printing surface (convex surface of the screen), then on the ink surface (concave surface of the screen), usually three times on each side. _

(3) The net is then dried for the first time. (Note: Line and character screen printing needs secondary coating)

(4) If thick screen plate is required, then it can be brushed several times, that is, after the first coating, it is immediately put into the oven at 30-40 C to dry, take out the screen and coat again. According to the required thickness, the number of times of coating is decided. It should be noted that the general printing surface (convex surface) is coated 2-3 times more than the ink surface (concave surface), and this operation is the second. Secondary coating. (Note: The coating is only carried out on the contact surface of the wire mesh). Dry it with a hairdryer or oven. There should be no empty drying or no drying, so as to avoid affecting the quality of plate making. (Note: Shedding photosensitive glue) Note: The gluing process is very important. The quality of screen plate depends entirely on gluing, requiring uniform thickness and stereoscopic impression.

3)Drying

After the screen printing photosensitive glue is painted, it is placed for 1-2 minutes, then the screen is dried in an oven at about 40 C. After drying, it is removed and put in a dark frame for use. Note: Screen must be dried, otherwise it will affect the firmness of the screen.